Nowadays, every business uses heating applications in one way or another. Our daily lives are significantly impacted by the heating. Concerns about the efficiency of many of the heating solutions being utilized, as well as their effects on the environment and safety, are becoming more and more prevalent as the reliance on heating applications increases. Many of the other typical methods produce a lot of carbon dioxide and other pollutants that pollute the environment, even if some of the systems are susceptible to fire incidents.

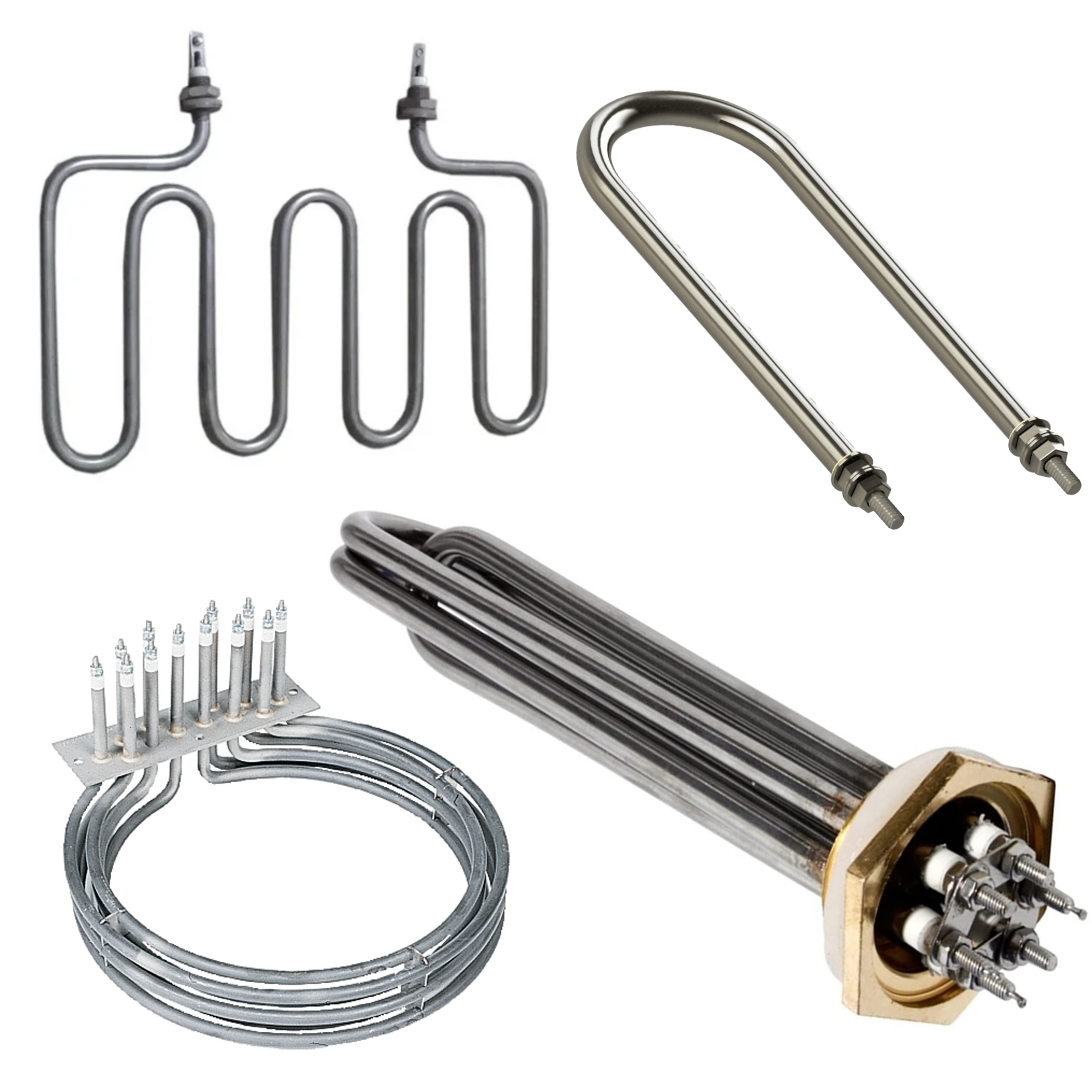

One of the greatest choices for the current world is a tubular electric heater, which is the safest method of heating any liquid or surface without releasing any harmful gases.

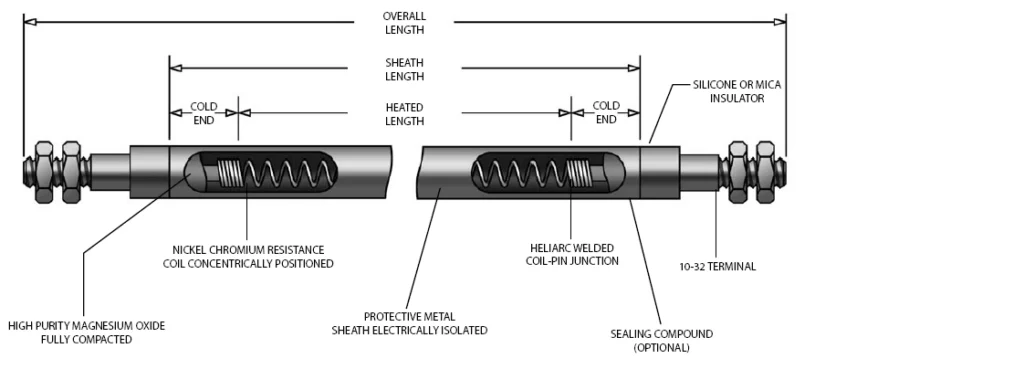

Typically, a resistivity coil enclosed in a metal tube filled with insulating materials like magnesium oxide is used to create tubular heaters. No electric shock is transmitted to the exterior thanks to the heating coil, which is positioned in the middle with uniform pitches and is isolated from the outer metal sheath by compacted magnesium oxide. All of the generated heat energy is simultaneously transmitted to the process via the external body. Thus, the heater is considered to be among the safest and most effective heating options.- NOBLEHEAT

Nickel Chromium Resistance was uniformly coiled wire is stretched through the active length of the element. The ends are proved with the terminal pins to create cold ends.

Magnesium oxide: High purity magnesium Oxide power is filled between the coil and outer tube in an automated filling station to ensure the right insulation, conduction as well as compactness.

Outer sheath: Tube (welded or seamless) which acts as outer protection for the Heating Element. The selection of the outer tubes depends on various factors such as temperature, pressure, fluid to be heated, etc.

Terminal pins: Also known as terminal pins are extended ends of the heating elements. The SS rods of a specific diameter is fusion welded to the coils at both ends. The length of the rod depends on the non-heating length required for any application and installation.

End Sealing: Sealing is done using the combination of Ceramic beads, soft seals & sealants. The sealing ensures that no moisture from the atmosphere enters the heating element and keeps it dry.

| Sheath Material | Copper, Stainless Steel (SS304, SS316, SS321), Incoloy, Titanium, Other alloys as per application selection |

| Watt Density | Up to 120W/m² or 47W/cm² |

| Sheath Length | Up to 10 meter |

| Diameter | 6mm, 8mm, 11mm, 12.5mm, 13.7mm, 14.5mm, 16mm and 18mm |

Teflon Seal: Teflon seal is used where effective sealing is required against moisture and oil contamination.

Silicon Rubber Seal: Most popular and highly used sealing method. The sealing can withstand up to 200 deg C temperature and provides long-lasting moisture protection.

Epoxy Seal: Epoxy potting forms a good moisture seal with more mechanical strength than a silicon rubber seal. Recommended for a system assembly with a large no of tubular elements.

Cement: recommended for the heater which operates at very high skin temperature. Provides protection against high viscous fluids and dusts. The top layer can be provided with a additional insulation to make it moisture resistance as well.

| Material | Application |

|---|---|

| Copper | General purpose heating |

| Stainless Steel | Water, Oil, Grease, metal surface heating |

| Immersion Heating's in Water, Alkaline cleaning solutions, Tars | |

| Mild Corrosive liquids, food processing equipment | |

| Indirect and Radiant heating | |

| Air heating/ Gas heating. Hopper & tank heatings | |

| Large process plant applications | |

| Alloy 800 | Cleaning and degreasing solutions, Corrosive liquids / gases |

| High temperature / High pressure | |

| Alloy 600 series | Plating and pickling solutions, acid |

| Titanium | High Corrosive liquids |

Discover how our expert heating solutions help you save time, reduce costs, and minimize effort—making efficiency simple and hassle-free. With our tailored approach and dedicated support, achieving your operational goals has never been easier. Contact us today to learn more and start saving!

NobleHeat Heating Technologies

Do not want to miss any news, updates, notice or any offer on our products, then please subscribe to our mailing list.

Copyright © by nobleheat.com. All rights reserved.