With all safety measures incorporated into the heater and control system, a single bundle or several smaller units can be mounted in the tank to provide consistent heat transfer and stable fluid heating.

Immersion heaters are always the finest option for any production or processing facility where a big volume of fluid needs to be heated before being pumped out to a process application. With all safety measures incorporated into the heater and control system, a single bundle or several smaller units can be mounted in the tank to provide consistent heat transfer and stable fluid heating. – NOBLEHEAT

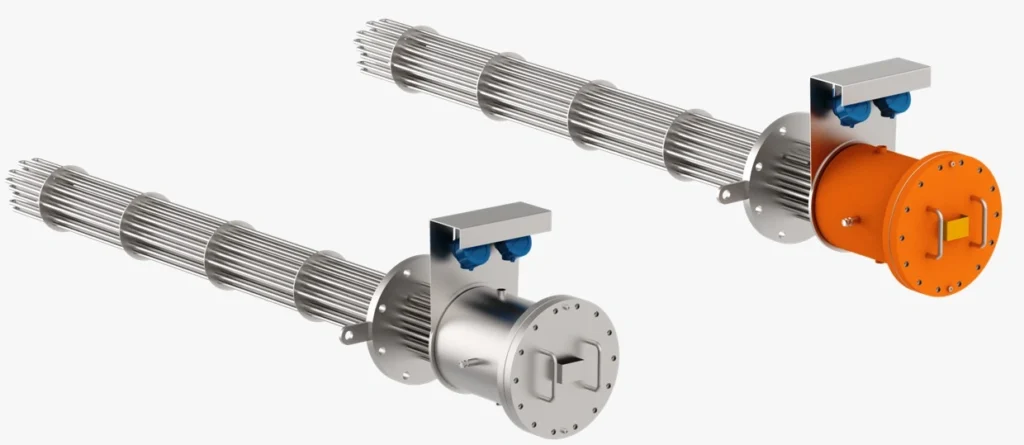

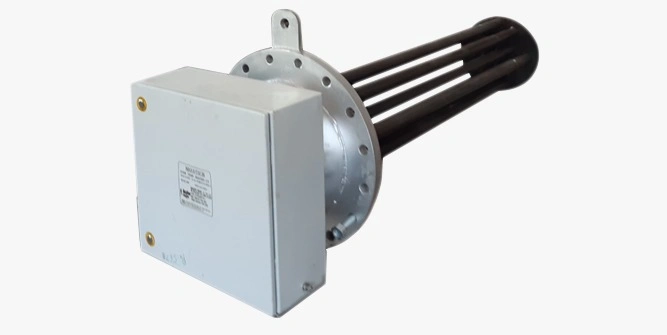

Terminal Enclosure: Marathon flameproof heaters are certified to install in hazardous areas Zone 1 & 2, Gas group IIC, IP66. The Terminal enclosure is designed to protect the terminals of the individual elements from external impacts, such as dust, moisture, etc, and to facilitate the connection of the Incoming power supply to the heater bundle.

Heater Bundle: Consist of No. of U Pin heating elements adequately supported by a set of Baffles & Tie rods, designed to deliver the specified temperature at the outlet by maintaining the element temperature & pressure drop within the safe limits. Heating elements can be fixed to the heater flange by means of standoff sleeve pipes with brazing or direct welding or by means of threaded couplings. The heat duty of a bundle can be divided into many subgroups (banks) based on process conditions. This will help in better control and flexibility in the operation.

Temperature Sensors: The Heater bundle will have an Element skin temperature sensor for monitoring and regulating the Element skin temperature within the limits. The Unit may also need additional sensors such as Tube sheet Temperature Sensor, Terminal Box Sensor, vessel Body temperature sensor, and process fluid Temperature sensors based on case-to-case. The Sensors used for the system will be certified in accordance with the area of installation. The Temperature sensors are Typically RTD or Thermocouple. A simple heater bundle can also be controlled using Thermostat protection for skin & process temperature. If the Operation pressure is High, It is recommended to have a PSV (Pressure Safety Valve) installed within the Heater Vessel as an additional safety measure.

Control Panel: Heater controls Panels are designed to monitor & control the operations of the heater bundle also to ensure the safety of the equipment and operations. The control logic can be either ON/OFF (contactor) or regulated (Thyristor) or a combination of both in a single panel. The control panels can be installed in both safe areas & hazardous areas by following respective design guidelines & certification requirements. The Control Panels are provided with various indication systems such as Power ON, Heater ON-OFF, Trip, High Temperature, etc for comfortable handling of the process. The Temperatures of Elements, Process fluid & other areas (with sensors) are displayed on the Panel for better monitoring & awareness. Control Panel will also have safety interlocks such as high element temperature, Earth fault, process over-temperature, etc along with Emergency stop access for the safe operation and control.

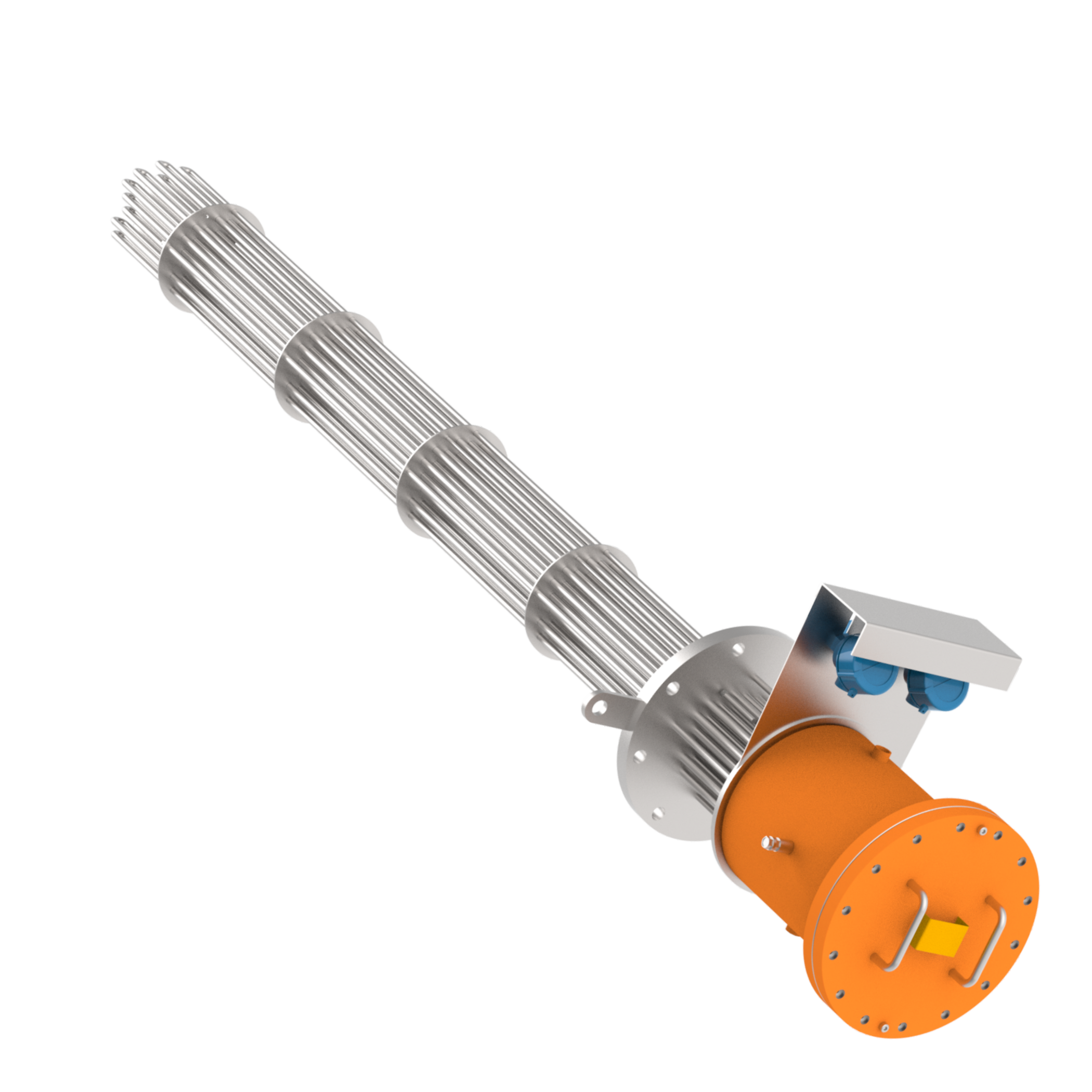

An Electric Heater bundle in which the heating elements will directly immerse into the fluid to be heated is known as direct Immersion Heaters. The Direct immersion heaters are compact-sized heaters with direct heat transfer, making them a very effective method for heating large volumes of stored fluids.

The Direct Immersion Heaters can be further designed as:

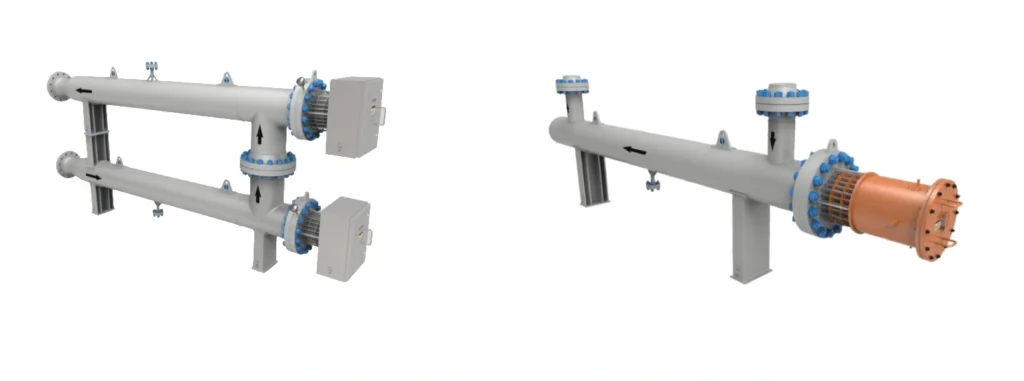

Horizontal Installed: Known as Horizontal Immersion Heater. Usually installed little above the bottom of the tank (always below the lowest fluid level)

Vertical Installed: Known as Vertical Immersion Heater. Usually installed from the top of the Tank. A proper design is important to ensure correct cold length to avoid hot spots and dry heating in this design.

Vertical Installed with Horizontal heating: Specially designed heater bundle is installed from the top using a flange or Threaded connection. The cold portion of the elements will be vertical up to the minimum oil level. The active areas of the elements are bent at 90 deg so that it always remains immersed in the fluid (similar to that of a horizontal immersion heater) The mounting arrangement can be with a Flange or with a Threaded Nut assembly based on the rating and application. The heater can be designed for both Safe area installation as well as hazardous area installation.

Direct Immersion heaters are most recommended due to their fast heating and compact sizes.

There are many fluids in which installation of a direct immersion heater remains a challenge. While in some fluids the heating elements fail within a few days of installation due to corrosion caused by the fluid, there is also a risk associated with the skin temperature and flashpoint of the fluid. Some unforeseen overheating or flashover may result in the accident (if control is not adequately supportive). For all such applications, Marathon heaters have been designed as “INDIRECT IMMERSION HEATERS”.

The heating elements are fitted to thread Nuts and are placed inside Casing Pipes welded to the heater flange. Thus the heating elements will never be in direct contact with the fluids. The heat transfers to the fluid through the thick casing pipe wall, which will be heated by the elements present inside. The Bundles are mostly used in Horizontal installation in both safe areas as well as hazardous zones. The System provided full safety from any overheating & flashover inside the tank. Another advantage of an indirect Immersion heater is < even in case of any failure of the single element, the replacement can be done without draining the tank. Hence the downtime & cost of maintenance spares is reduced to a great extent.

| Rating | From 0.1 1kW to 5000kW (Max) in Single Bundle or combination |

| Design Temperature | -40°C to 650°C |

| Design Pressure | Up to 350 bar(g) |

| Element Outer Sheath | SS, Alloy 600 series, Alloy 800 series, Hastelloy, Titanium, copper, etc |

| Heating Elements | Mineral-filled insulated Heating Elements or Tubular heating Elements with Ni-Cr (80-20) as heating Coil and suitable outer sheaths |

| Terminal Enclosure | As required (Weatherproof or Flameproof) |

| Control System | Thermostat control / Contactor control / Thyristor control / combination |

| Protections & Control | Element Skin Temperature Control, Process Temperature Control, Earth Leakage Protection, Overload Current Protection, Temperature Class Protection (for Hazardous area only) |

| Installation | Horizontal / Vertical / direct / indirect |

| Certification | Will be provided based on Requirements (U, U2, ATEX, IEC Ex, CCOE, etc) |

Discover how our expert heating solutions help you save time, reduce costs, and minimize effort—making efficiency simple and hassle-free. With our tailored approach and dedicated support, achieving your operational goals has never been easier. Contact us today to learn more and start saving!

NobleHeat Heating Technologies

Do not want to miss any news, updates, notice or any offer on our products, then please subscribe to our mailing list.

Copyright © by nobleheat.com. All rights reserved.